Behind blue

Blue is part of our DNA. At MoldBrothers, we understand the chef’s challenges, like precision, timing and consistency. We turn these challenges into opportunities for creativity. Our molds are built around intent, perform with accuracy and are reliable for every service. By merging creative thinking with industrial precision, we support the philosophy of chefs worldwide. MoldBrothers is your culinary design studio with the capacity to produce at scale.

Behind blue

Blue is part of our DNA. At MoldBrothers, we understand the chef’s challenges, like precision, timing and consistency. We turn these challenges into opportunities for creativity. Our molds are built around intent, perform with accuracy and are reliable for every service. By merging creative thinking with industrial precision, we support the philosophy of chefs worldwide. MoldBrothers is your culinary design studio with the capacity to produce at scale.

Behind blue

Gastronomy takes shape in blue

Blue is part of our DNA. At MoldBrothers, we understand the chef’s challenges, like precision, timing and consistency. We turn these challenges into opportunities for creativity. Our molds are built around intent, perform with accuracy and are reliable for every service. By merging creative thinking with industrial precision, we support the philosophy of chefs worldwide. MoldBrothers is your culinary design studio with the capacity to produce at scale.

“For us, blue represents more than a color. It stands for quality, precision, and authority. Not claimed, but earned through design, material choices, and use in real kitchens.

Behind Blue gives language to what lies beneath that blue: the thinking, the standards, and the decisions that determine why our products perform as they should, day after day.”

Blue is more than the color of our molds. It represents the quality beneath the surface.

We could make our molds in any color, but blue is a deliberate choice. Not for visibility, but for meaning. It reflects our focus on what lies behind the product, material decisions, precision, and performance that hold up in real kitchens.

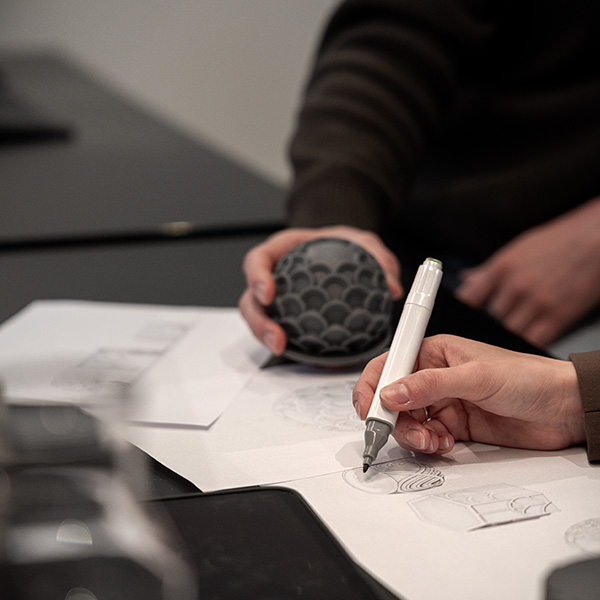

Design always a choice. In fine dining, every shape carries intention. Simplicity is often the right answer, but never by default. Choosing a form requires the same deliberation as choosing a flavor. Design sits at the core of everything we do, translating ideas into functional tools shaped by context, use, and environment, not convenience.

Our reference point is reality.

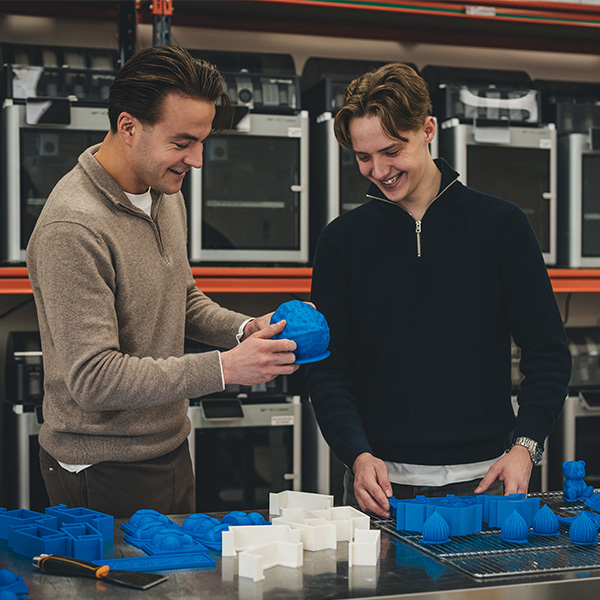

We work closely with chefs, think like them, and test our tools where they are meant to perform: in professional kitchens. Products are validated through use, not visuals. We look beyond the mold itself — understanding what our clients aim to achieve, and taking responsibility for the technical execution.

Blue is never finished.

Techniques evolve, materials improve, and expectations shift — inside and outside our company. It is our responsibility to learn, adapt, and refine continuously. Whether the challenge is technical or logistical, we do not accept limitations simply because they are common practice. Improvement is an ongoing commitment.

2017

Silicone molds have been a part of the kitchen since the El Bulli. Brothers, Joost (former chef) and Stijn (business student) saw an opportunity to combine their passion for food innovation, hospitality and entrepeneurship. That is how MoldBrothers was born.

2018

The brothers sell their PlayStation 4, and everything they could spare, to get their business started. With limited resources but clear goals, they set up shop in their parents’ garage.

2020

Momentum followed quickly. As demand increased, the garage no longer sufficed and MoldBrothers moved into its first dedicated office and production facility.

2021

Momentum followed early. Through close collaboration with leading chefs —especially during the COVID period —MoldBrothers pressure-tested its products in real kitchens, laying the foundation for its global reach.

2022

As the community grew, so did the ambition. The MoldBrothers TestKitchen became the playground for innovation. A space to explore new products, recipes and techniques to stay ahead in the ever-evolving culinary world.

2023

Just a few hundred meters away, a new facility offered room to grow. This space was transformed into a fully professional production environment with offices, built to support the next decade of innovation. chefs — especially during the COVID period — MoldBrothers pressure-tested its products in real kitchens, laying the foundation for its global reach.

2024

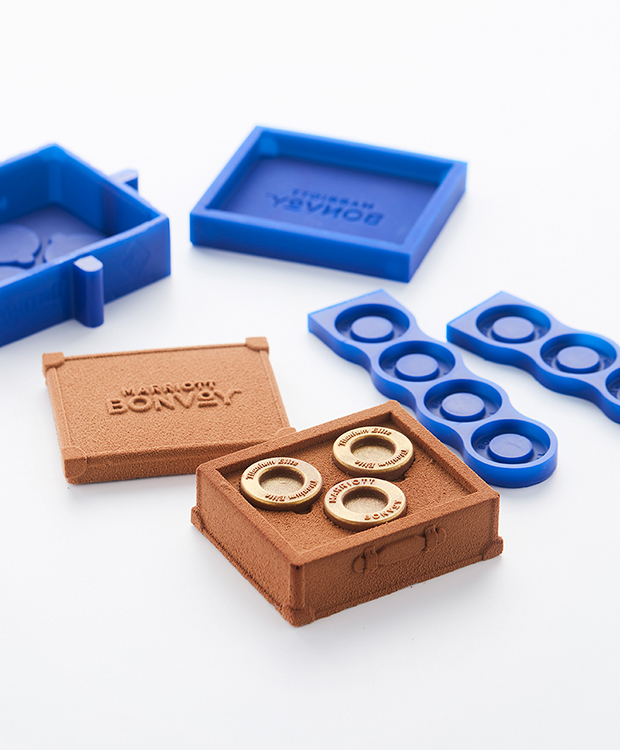

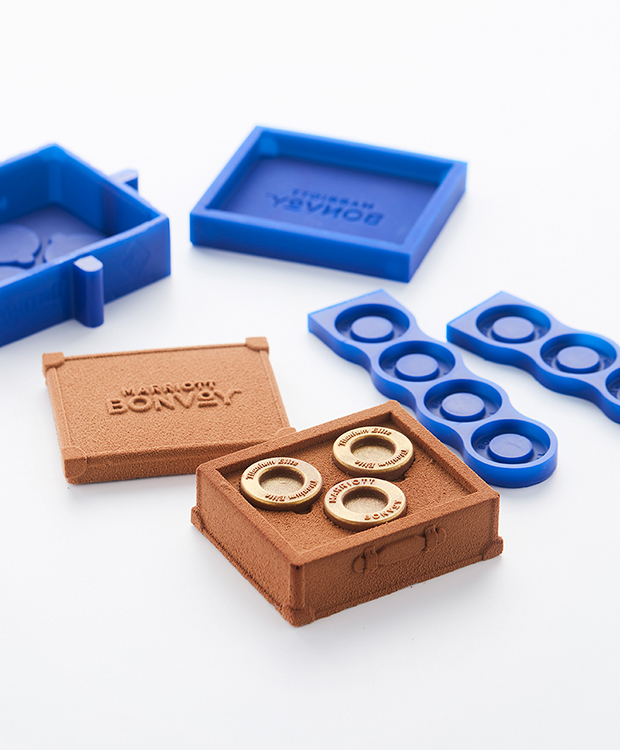

An increasing demand for custom pastry solutions from luxury hotels and pâtissiers led to the relaunch of MoldBrothers Pastry. The same blue principles, reinterpreted for the precision and artistry of pastry.

2025

We are proud to say that we work hard to maintain the biggest Silicone Mold community on Instagram with over 360k followers.

01/06

Creating silicon molds has long been part of kitchen experimentation. Brothers, Joost (former chef) and Stijn (business student) saw an opportunity to combine their passion for food innovation and hospitality. That is how MoldBrothers was born.

02/06

The brothers sell their PlayStation 4, and everything they could spare, to get their business started. Operating on a shoestring budget, they setup shop in their parent’s garage. Within no time, their business outgrows the garage, and they need to find their first office and production facility.

03/06

In the early years, MoldBrothers focused on perfecting products and business. Collaborations with top chefs became essential to ensure every mold could withstand the real demands of the kitchen, heat, speed and precision.

04/06

As our community grew, so did our ambition. The MoldBrothers TestKitchen became the playground for innovation. A space to explore new molds, recipes and techniques that keep us ahead in the ever-evolving culinary world.

05/06

Working closely with luxury hotels and pâtissiers worldwide for custom work, we relaunched MoldBrothers Pastry. The same blue principles, adapted to the art of pastry.

06/06

We are proud to say that we work hard to maintain the biggest Silicon Mold community on Instagram with over 360k followers.

Our webshop exists for a simple reason. We believe chefs should not have to custom-design a mold for every idea. Many shapes return, evolve, and find new meaning across dishes, menus, and kitchens. By making these forms directly available, the webshop gives chefs access to tools that support their work consistently, without dominating the plate.

It is a place where considered shapes become practical, ready to be used whenever creativity calls for them.

At the same time, some ideas need a shape of their own. Our custom work exists for dishes with a clear intent that cannot be translated through existing forms. We work closely with ambitious, curious makers, taking part in the creative process to understand the idea behind a dish, how it functions in service, and how material and shape interact.

As our technical knowledge continues to grow, so do the possibilities. So chefs can focus on creativity, while we take care of shape

We have set-up our own TestKitchen to transform creativity into execution. A place where we innovate on not only products, but also recipes.

A young and dynamic team of over 30 professionals with a combined passion and enthusiasm for fine dining, creativity and innovation.

MoldBrothers is a creative food design studio with the capacity to produce at scale. We create custom designs upon request and produce and sell products via our webshop.

All of our products are designed and produced in the Netherlands.

MoldBrothers is located in Wijchen, the Netherlands. But no worries, we can be all around the world, if needed!