En MoldBrothers, a medida significa realmente a medida. No se trata de soluciones semipersonalizadas, sino de herramientas totalmente a medida diseñadas para funcionar exactamente como se necesita. Tanto si se trata de un molde hecho para ser eficiente y diseñado para adaptarse a una bandeja gastronorm 1/1 completa, como de un molde tuille construido para resistir el transporte por terreno accidentado hasta un local de catering, el objetivo define el diseño.

Facilítenos la información adecuada, y tendremos todos los ingredientes para crear una herramienta que haga el trabajo.

Los moldes Tuille han formado parte de MoldBrothers desde el principio. Años de desarrollo han dado forma a lo que funciona. Desde formas abstractas a naturales, los tuilles permiten más libertad en la técnica y la aplicación de lo que a menudo se espera.

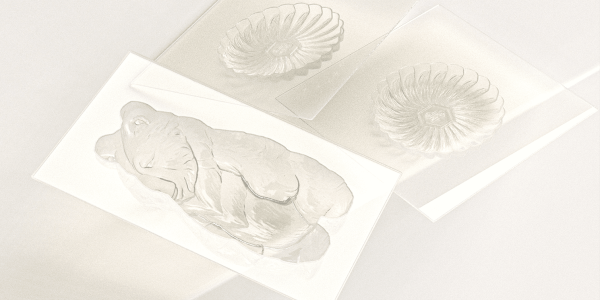

El termoformado también es un método probado para dar forma al chocolate. Utilizando matrices de alta calidad, podemos empezar en pequeñas series. Adecuado para barras, objetos o conceptos personalizados, en diferentes grosores de material.

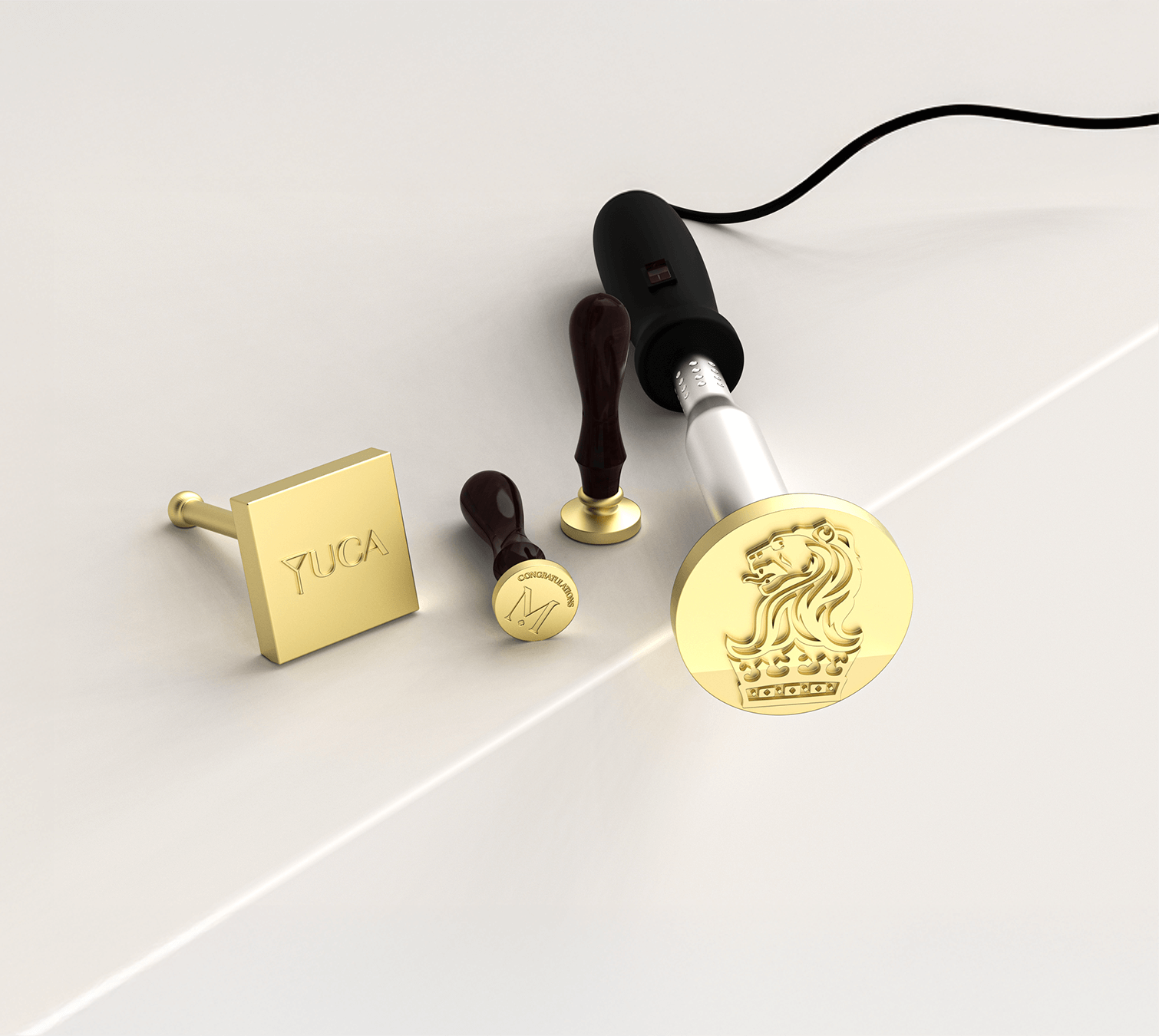

Desarrollamos sellos a medida para diferentes aplicaciones. Desde hierros de marcar hasta sellos de Buñuelos. Los sellos de latón pueden utilizarse a mano, lo que permite transferir logotipos o marcas sólo con el calor.

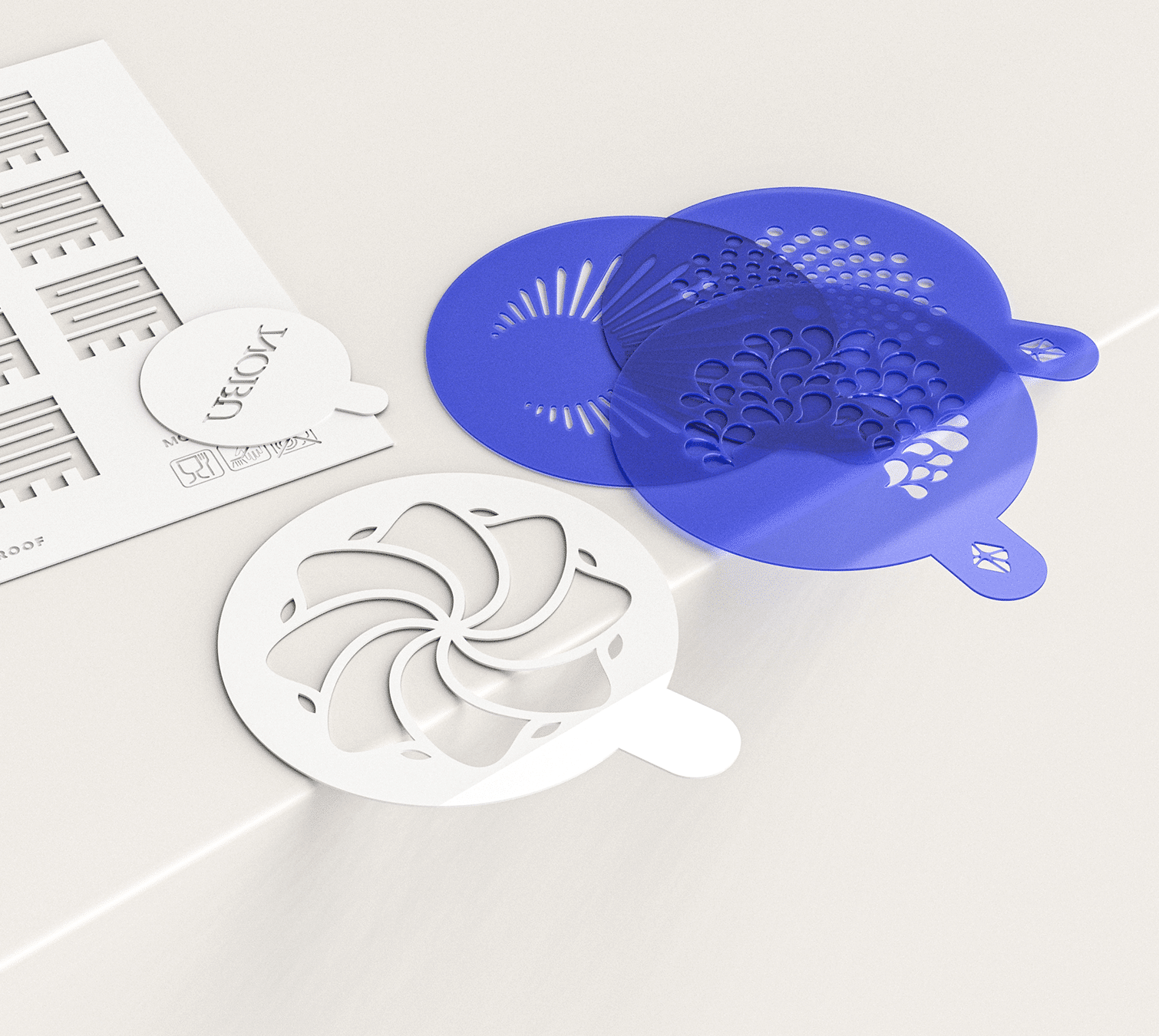

Las plantillas pueden fabricarse en casi cualquier tamaño. Desde el polvo fino hasta el uso en gran formato. Diseñamos las plantillas en función de su aplicación, centrándonos en la claridad de las formas y la facilidad de uso.

Las cortadoras personalizadas se desarrollan en torno a lo que usted desea moldear. Desde contornos de logotipos hasta bases ajustadas. Fabricados con materiales seguros para los alimentos, diseñados para adaptarse a su producto en lugar de forzar un tamaño existente.

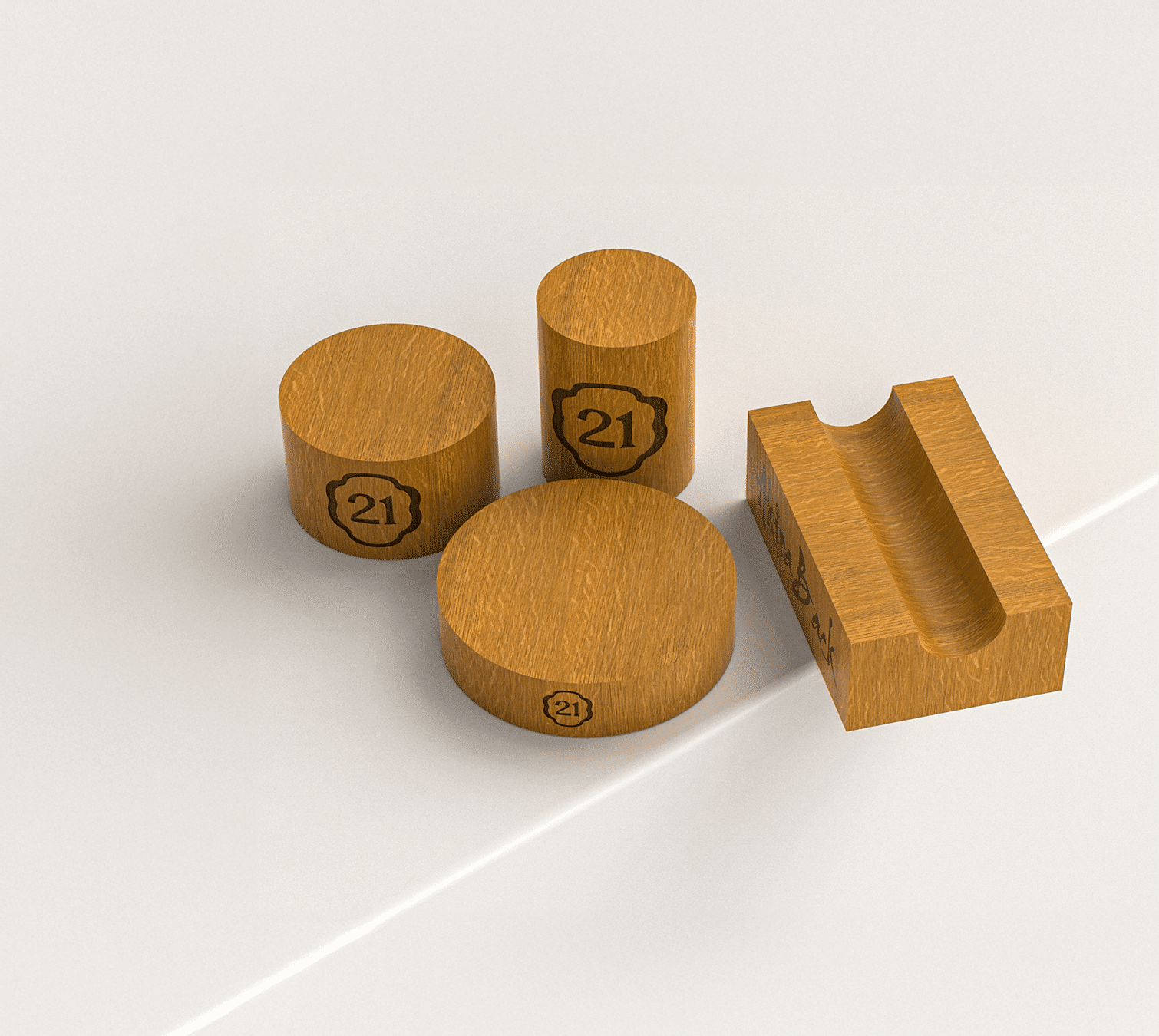

Nuestros presentables pueden personalizarse o desarrollarse a medida. Las piezas existentes pueden personalizarse o crearse nuevas formas. Diseñados para apoyar el plato sin desviar la atención de él.

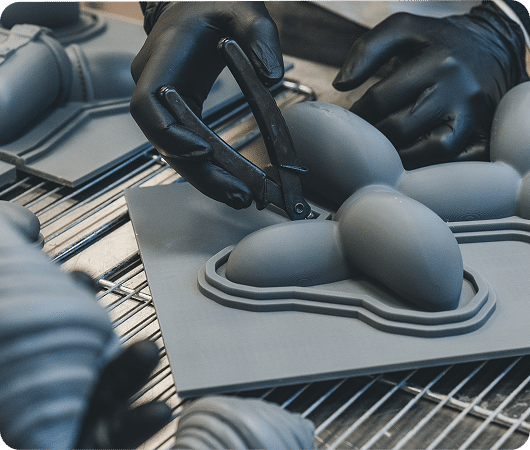

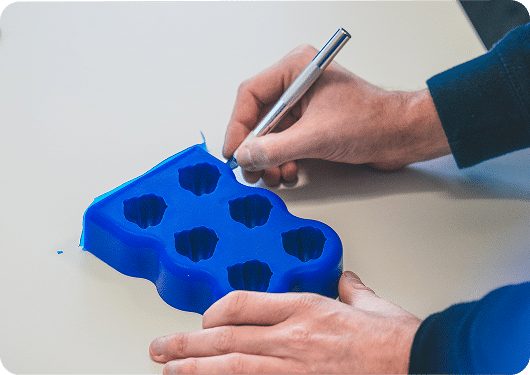

Los moldes de silicona son la base de todo lo que hacemos. Son nuestra herramienta más versátil: una solución fiable para una amplia gama de retos técnicos y creativos. Gracias a nuestra producción propia, desarrollamos Moldes 3D, moldes tuille, kits de prensado y mucho más, para aplicaciones que van desde la congelación de mousses a -40 °C y crèmeux, hasta hornear tuilles a temperaturas de hasta +200 °C. Cuando se requiere flexibilidad en los procesos, la silicona es la elección natural.

Su rendimiento va más allá de la congelación y el horneado. Los moldes de silicona funcionan excepcionalmente bien con el chocolate, lo que permite obtener detalles refinados y precisos. Cuando es necesario, combinamos silicona flexible con carcasas de apoyo impresas en 3D para garantizar la estabilidad durante el llenado y la congelación, sin comprometer el desmoldeo. Trabajamos con mezclas de silicona con distintos niveles de dureza, asesorar sobre la composición óptima para cada aplicación, y producir con un MOQ de 1.

Cuando se trabaja con chocolate, entendemos que el brillo y el lustre son esenciales, cualidades que son más difíciles de conseguir con moldes de silicona. Nuestros moldes de termoformado proporcionan un bajo coste inicial alternativa a los moldes de policarbonato a medida, con un MOQ de sólo uno, lo que los hace accesibles para tabletas, bombones y amenities de chocolate personalizados. Además, los moldes termoformados ofrecen plazos de entrega mucho más rápidos en comparación con las soluciones tradicionales de policarbonato a medida.

En la práctica, la combinación de moldes termoformados con moldes de silicona suele ofrecer los mejores resultados para las amenidades de chocolate, equilibrando el acabado superficial, la flexibilidad y la libertad creativa.

Los sellos se definen por la intención. La decisión más importante no es la forma en sí, sino el papel que el sello desempeña dentro de un plato o servicio. Tanto si se utilizan para refinar sellos de chocolate como para marcar panecillos de hamburguesa a fuego abierto, el resultado previsto dicta todas las decisiones técnicas que se toman a continuación.

En nuestro programa de sellos no hay limitaciones fijas de tamaño o forma. Los sellos se fabrican en acero inoxidable o latón, con configuraciones totalmente adaptadas a su uso. Cuando la consistencia y el control de la temperatura son esenciales, un elemento calefactor eléctrico integrado pueden aplicarse. Para aplicaciones a fuego abierto o a la parrilla, los sellos pueden equiparse con la empuñadura de su elección, Incluye asas extendidas para mayor seguridad, alcance y control. Con un MOQ de uno, Cada sello se desarrolla para apoyar la técnica, nunca al revés.

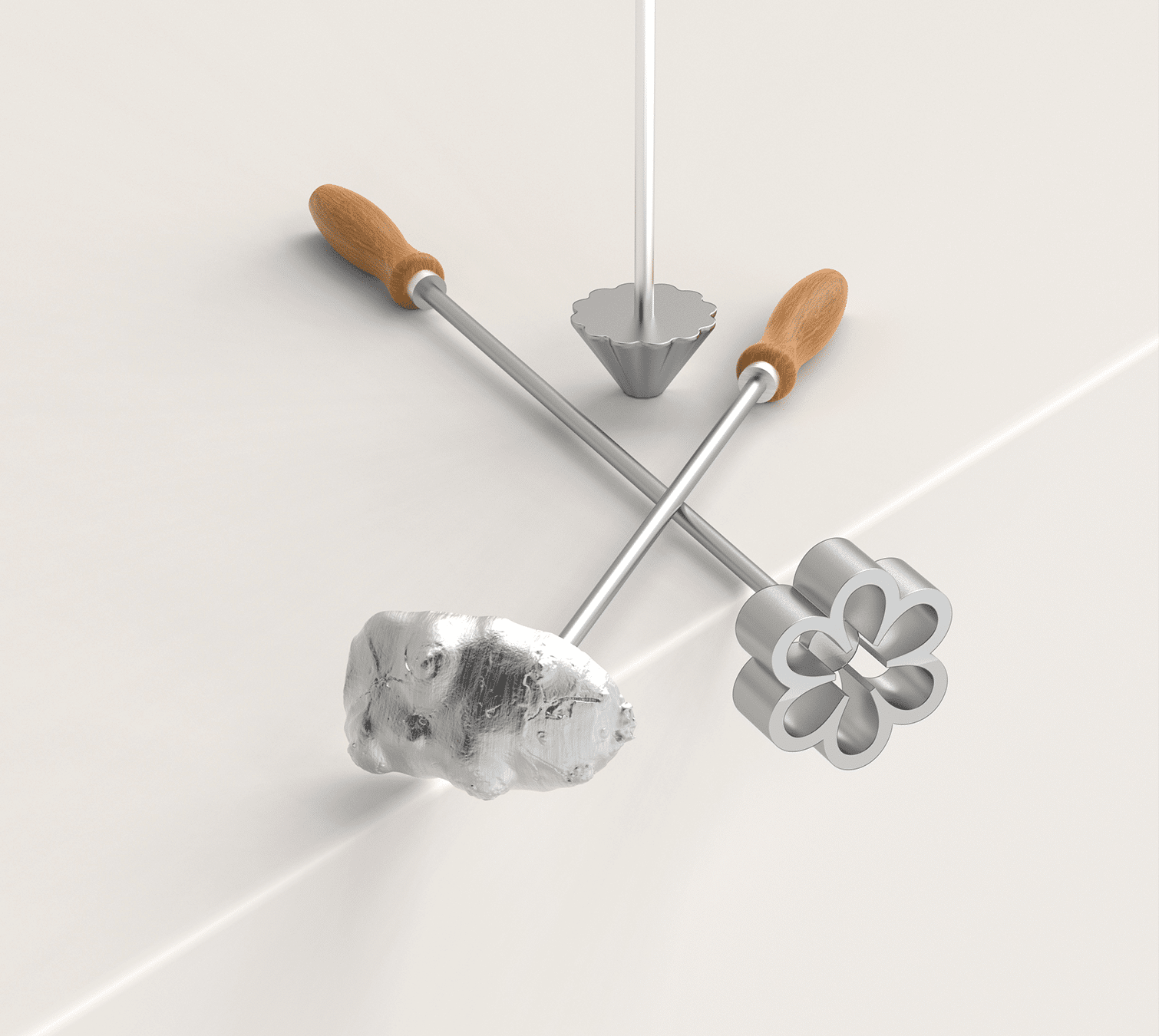

Los buñuelos y las tes para tartas son herramientas diseñadas para obtener precisión en las patatas fritas. Su geometría cónica garantiza una expansión controlada, un grosor uniforme y un resultado limpio y definido en cada uso. Desde logotipos hasta formas abstractas más complejas, siempre que la geometría pueda traducirse en una forma cónica, puede hacerse funcionar.

Fabricadas en aluminio, estas herramientas combinan durabilidad y velocidad con una conducción óptima del calor, lo que las hace ideales para crear tartaletas crujientes y uniformes. Están disponibles en varias configuraciones: como unidades individuales con un solo mango y cabezal, o como una solución de varias unidades en forma de nuestra cesta para tartaletas, que permite utilizar hasta cinco tartaletas simultáneamente.

A menudo olvidadas, las plantillas son una de las herramientas más versátiles de la cocina. Cada plantilla se desarrolla con un objetivo claro, con material, grosor y formato seleccionado para que coincida con el resultado previsto.

Disponible en formatos que van desde plantillas capuchino y plantillas plato a A3, se utilizan habitualmente para patatas fritas isomalt, polvos, tuiles y merengues afilados, por sí solas o en combinación con kits de prensado. El grosor puede especificarse a partir de láminas ultrafinas de 0,5 mm hasta construcciones rígidas de 20 mm, en función de la aplicación.

Producido en silicona, PS, acrílico o Mylar, cada plantilla está configurada para admitir la técnica, siempre que se defina el resultado.

Nuestros cortadores impresos en 3D son una herramienta económica pero muy práctica. Aunque no son tan afilados como nuestros sacabocados de acero inoxidable, rinden excepcionalmente bien al cortar geles cuajados, verduras cocidas, pâte sablée y una amplia gama de preparaciones similares.

Diseñadas para ofrecer versatilidad y facilidad de uso, constituyen una solución eficaz cuando se requiere precisión sin necesidad de herramientas metálicas.

Los presentables se han convertido en parte integrante de nuestro proceso personalizado. Ciertas creaciones requieren una herramienta diseñada específicamente para su presentación. Personalizamos totalmente los presentables para que se adapten a su servicio de mesa, no solo en la forma, sino también en los detalles.

Los presentables existentes pueden grabarse con láser con logotipos o diseños gráficos, mientras que los diseños totalmente a medida pueden desarrollarse desde cero. La elección de materiales es igualmente flexible, desde la madera de nogal hasta la superficie sólida, lo que permite que el presentable se adapte perfectamente tanto al plato como a su contexto.

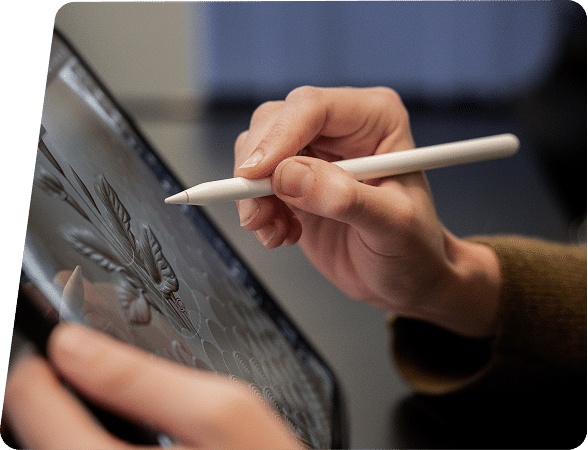

El proceso personalizado

Comparte tu idea haciendo clic en el botón de abajo, o ponte en contacto con nosotros a través de Instagram, correo electrónico, WhatsApp o teléfono. ¿Lo necesitas rápido? Solicítalo ahora.

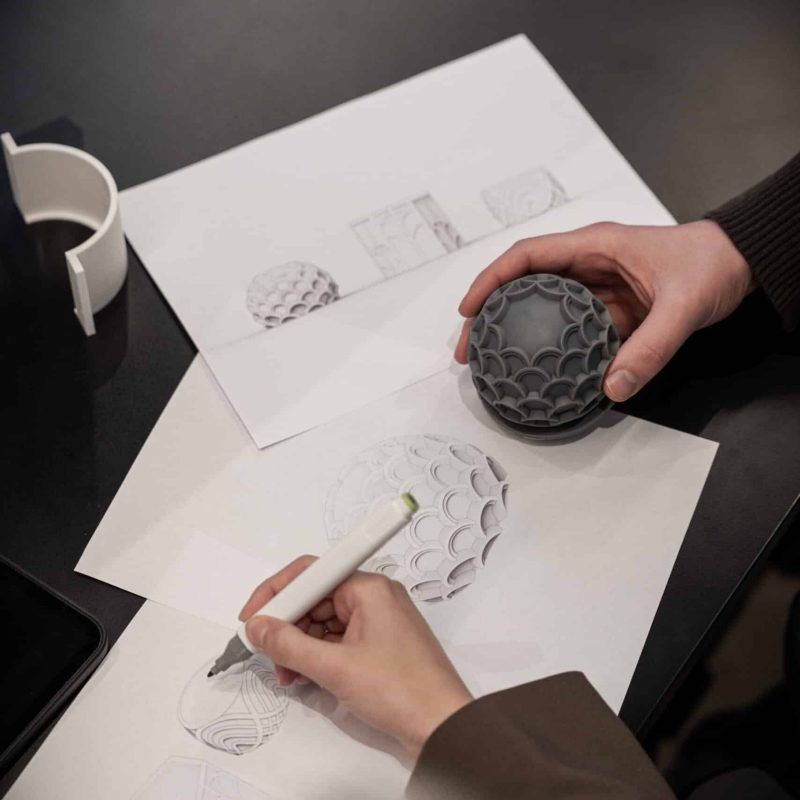

Una vez que su visión está clara, empezamos con un diseño gratuito que muestra cómo puede tomar forma su idea. Todos los diseños van acompañados de un presupuesto adaptado a sus necesidades, para que no se lleve sorpresas más adelante.

Tras la aprobación, su concepto cobra vida. Donde la creatividad culinaria se une a la precisión industrial, dando como resultado un molde listo para su cocina.

Nuestra capacidad de producción garantiza la uniformidad, incluso a gran escala. Sus productos se fabrican en los Países Bajos. Con la consistencia y la calidad que corresponden a su cocina.

Realizamos envíos a todo el mundo con FedEx, asegurándonos de que su pedido llegue seguro y a tiempo para que pueda disfrutar de sus productos. Y, por supuesto, estaremos a su disposición para cualquier ayuda o consejo. Estamos aquí para ayudarle.

Jan Hartwig Restaurante JAN

Jan Hartwig Restaurante JAN

Hans Neuner

Hans Neuner

Jeroen Achttien Inter Scaldes

Jeroen Achttien Inter Scaldes

Tim Raue Restaurante Raue

Tim Raue Restaurante Raue

Tanto si busca un producto estándar, Ya se trate de un molde de mantequilla personalizado o de un friandise entero, sus ideas merecen precisión, creatividad y un acabado impecable. Su idea toma forma en azul.